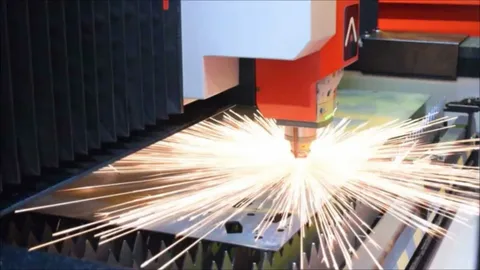

Stainless steel is an alloy which has had a superior demand due to its corrosion resistance, strength and also appearance. It is a blend of iron and chromium and it also forms a thin film that protects it against rusting. Furthermore, it can be used in various areas, including architectural applications and automobile applications. To produce finished stainless-steel products, various methodologies are employed in processing raw stainless steel. However, opt for the stainless steel beam laser cutting Dubai, which specialises in precision stainless steel beam laser cutting for use in construction, industry, and the architectural stream. The process employed here depends on the grade of stainless steel and the final product.

The Important Role of the Laser Cutting in Stainless Steel Fabrication

It makes it apt to create stainless steel components using laser cutting owing to the precision, performance and flexibility of the treatment. It is a thermal process all that involves directing a concentrated source of light (laser) to fuse, burn, or vaporise material in a localised area, resulting in a clean and high-quality edge. It has now emerged as an approach compared to cutting methods in most applications.

- Precision and Edge Quality: High precision is one of the greatest advantages of laser cutting. The fine cut and very focused beam enable precise and complex designs with tight tolerances that cannot easily be met with other processes. It is a critical requirement of stainless steel since such stainless steel is often used in applications that need to measure the part dimensions, e.g. in medical equipment and aircraft components. The kinematics of the process also results in a smooth edge that does not require secondary finishing operations. Not only does this save labour and time, but it also minimises the possibility of part damage in the handling process.

- High Speed and Efficiency: Laser cutting is a very quick process that may greatly enhance production. It can seamlessly cut varied thicknesses of steel plates, including thin sheets and thick plates, at a constant pace and high accuracy. Automation of the process, often through computer numerical control (CNC), permits a process with minimal human input. Moreover, this results in lower labour costs and shorter finishes of completed parts. The possibility of nesting products in a single sheet of material is also used to optimise material utilisation and reduce material waste, a critical determinant of cost-effective processes.

- Material Versatility and Flexibility: Not only is laser cutting not restricted to one grade of stainless steel. It is capable of efficiently cutting a broad set of stainless-steel alloys and other special grades. Moreover, the fabricators can complete different projects with the same equipment due to flexibility. The machine is also versatile to different cut thicknesses and shapes as long as the laser power and speed are set. Besides, this flexibility unveils the potential of the company to make an extensive range of products that comprises complex multi-part assemblies. It is therefore useful with fragile materials or ones in precarious conditions since it does not show any attempt to scratch or deform the surface of a material.

- Reduced Material Waste and Cost Savings: Precision of laser cutting results in considerable material waste reduction. The thin kerf and the tightly nested parts on a sheet minimise the use of material, so there is minimal scrap. However, this is especially relevant to costly materials such as stainless steel. The efficiency and automation of the process also reduce the overall costs of production. By saving the labour cost spent on extra finishing processes and expensive manpower, laser cutting provides a cheaper alternative to even large fabrication jobs. In addition to cost savings, the regularity of the cuts lowers the rejection of parts.

- Intricate Design and Prototyping Capabilities: The advantageous aspect of laser cutting is its ability to generate all the complex and complicated geometries that cannot be produced mechanically. High precision parts, such as intricate geometry, small holes, and crisp corners, can be manufactured using complex computer-aided design (CAD) files. Moreover, this also makes it suitable as a prototyping tool in creating a new product and printing custom parts to meet a specialised application. The policies of traditional cutting tools no longer restrict designers all allowing them greater freedom to design creative shapes and characteristics.

- Minimal Thermal Distortion and a Small Heat-Affected Zone: Stainless steel is sensitive to heat, and overheating may produce warping, discolouration and also decrease in corrosion protection. Laser cutting solves this by producing a localised cut. The intense cutting and narrow beam width ensure a small heat-affected zone, typically measured in hundredths of an inch. It has the advantage that it reduces the likelihood of the material warping and its metallurgical characteristics altering. This is an important benefit of stainless steel; in cases with thin sheets or complicated parts, it does not ruin their integrity and final effect.

- Automation and Software Integration: Laser cutting systems are not only automated and controlled by Computer Numerical Control software. The inclusion ensures a smooth transition between design and production. A manufacturer can design a piece of CAD software and import the file directly into the laser cutter, which automatically creates the cutting path. It all eliminates the possibility of error during the setup process, and it ensures that all pieces are identical in the design. Automation ensures that the process is faster, besides being very repeatable and reliable, where production needs to be carried out in large quantities.

- Versatility in Cutting Different Material Thicknesses and Types: Although laser cutting is ideal for cutting thin stainless steel, more advancements now enable laser cutting to be used to cut thicker plates. High-powered fibre lasers can cut very thick stainless steel and are precise in their cuts. Its versatility does not end with the thickness of the materials to be cut: with the right settings, the same machine can be used to cut a wide range of materials, such as different grades of stainless steel. A single laser cutting machine makes it one of the most versatile assets of any fabrication shop, as it can cope with a wider variety of projects.

Final Words

To sum up, laser cutting is a technology that has gained essential importance in the stainless-steel work of today. The precision and speed of the process mean that it is possible to churn out complex designs and very close parts with minimal waste of material. This provides a clean edge, which can often eliminate the necessity of any additional processing. Moreover, industrial beam laser cutting is the most recent technological revolution, and it makes cutting processes in large-scale manufacturing enterprises much more efficient and precise. Its adaptability in welding varied gauges and grades of stainless-steel renders it a central pillar in custom and large-volume jobs alike, guaranteeing high-quality and expediency.